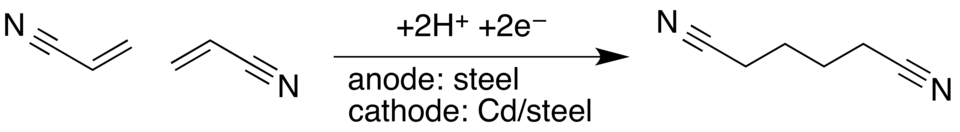

In terms of commercial electrocatalytic reactions,

there are actually very few. There are

electrowinning reactions, (i.e. electrochemical

reduction of metals salts), mostly notably the

Hall-Heroult process for aluminum, and the

electrosynthesis of halides, but beyond th at

there is very little. Though water

electrolysis to hydrogen is often hyped, most

electrocatalytic hydrogen comes as a byproduct of

chlorine evolution. In terms of organic

chemistry, there is really only one notable process

and that is the adiponitriled process as shown on

the right. Thus it is possible for the

economics to work, but we have just not been able to

find other reactions. One of my research

thrusts is to look in this direction. at

there is very little. Though water

electrolysis to hydrogen is often hyped, most

electrocatalytic hydrogen comes as a byproduct of

chlorine evolution. In terms of organic

chemistry, there is really only one notable process

and that is the adiponitriled process as shown on

the right. Thus it is possible for the

economics to work, but we have just not been able to

find other reactions. One of my research

thrusts is to look in this direction. |

|

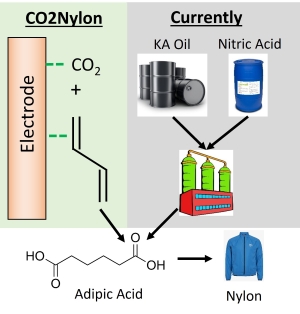

Valuable products One of the main reasons we have not been able to find economically viable electrosynthesis processes is simply because we have not cared to focus on it. A large amount of electrosynthesis research and development funding has been on fuels and bulk chemicals due to their large market value. However the lack of an emerging H2 economy after decades of effort has shown that another approach is needed. CO2 electrolysis does provide the potential for niche products such as isotopically labelled ethanol and ethylene synthesis (which I am involved in a start-up with), and I believe this can be a starting point for other products as well. While bulk chemicals such as ethanol and ethylene are 2.5 times more valuable than hydrogen on a $/MWh basis, other organics have the potential to be even higher. Aqueous based electrolytes are almost exclusively used in electrochemistry, however organics are not soluble in aquoeous solutions, thus we need to operate in non-aqueous studies. We have had a project recently analyzing CO2 electrolysis is non-aqueous solutions and our biggest finding was that while aqueous reactions allow for catalytic based inner-sphere reactions (i.e. sharing electron density with a catalysts), switching to non-aqueous reactions tend to favor outer-sphere reactions (i.e. non-catalytic), and thus much lower energy efficiencies. Thus one of our major goals is to figure out how to resolve this. Integrating electrochemistry into Nylon synthesis  About

6-7M tons of Nylon is produced every year, and this

is derived from reacting hexamethylenediamine and

adipic acid. Adipic acid is a 6-carbon chain

molecule that is typically produced via KA Oil

(fossil fuel derived) and nitric acid

(environmentally unfriendly) . Interestingly,

a few research works have shown that CO2

can be electrochemically reduced onto butadiene to

form adipic acid. While butadiene is normally

produced via fossil fuels, there is a non-negligible

market share that is produced via dehyrogenation of

ethanol, thus providing a sustainable approach to

butadiene. About

6-7M tons of Nylon is produced every year, and this

is derived from reacting hexamethylenediamine and

adipic acid. Adipic acid is a 6-carbon chain

molecule that is typically produced via KA Oil

(fossil fuel derived) and nitric acid

(environmentally unfriendly) . Interestingly,

a few research works have shown that CO2

can be electrochemically reduced onto butadiene to

form adipic acid. While butadiene is normally

produced via fossil fuels, there is a non-negligible

market share that is produced via dehyrogenation of

ethanol, thus providing a sustainable approach to

butadiene.This approach has substantial potential for economic viability, however the CO2 is currently reduced onto the butadiene via a high overpotential outer-sphere radical reaction rather than a more efficient catalytically driven inner-sphere reaction. Thus our goal is to work to achieve a catalytically active coupling of the CO2 and the butadiene. From a more fundamental aspect, this work will analyze how alkene behaves on an electrocatalyst at an applied potential, especially when compared to competing adsorbates such as hydrogen and CO. Given that alkenes is a pretty large class of molecules the overall scientific understanding could be quite broadly applicable. |

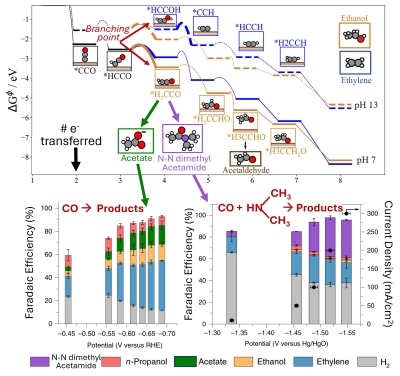

CO2

electrolysis coupled with amines

In

2019 a colleague of mine,

Professor Feng Jiao, was trying to analyze the mechanism

of CO2

electrolysis and inserted amines into the electrolyte to

help see if any of the intermediates would react with the

amine to form an amide. Fortunately it did and

this study, along with some of

our studies,

and further

studies by Professor Jiao & DTU computational chemists

all led to a pretty clear indication that CO2

electrolysis proceeds through ethenone, which then would

either desorb and hydrolyze to acetate or get further

reduced on the electrode to ethanol. This also demonstrated

that the step before the ethenone intermediate was the

branching point between ethanol and ethylene, the 2 major

products from Cu based CO2

electrolysis. This concept is shown on the figure to

the right, which is a mesh of

Jouny et al. Nat Chem. 2019. and

Kastlunger et al. ACS Cat 2023.

In

2019 a colleague of mine,

Professor Feng Jiao, was trying to analyze the mechanism

of CO2

electrolysis and inserted amines into the electrolyte to

help see if any of the intermediates would react with the

amine to form an amide. Fortunately it did and

this study, along with some of

our studies,

and further

studies by Professor Jiao & DTU computational chemists

all led to a pretty clear indication that CO2

electrolysis proceeds through ethenone, which then would

either desorb and hydrolyze to acetate or get further

reduced on the electrode to ethanol. This also demonstrated

that the step before the ethenone intermediate was the

branching point between ethanol and ethylene, the 2 major

products from Cu based CO2

electrolysis. This concept is shown on the figure to

the right, which is a mesh of

Jouny et al. Nat Chem. 2019. and

Kastlunger et al. ACS Cat 2023.

However what was forgotten in all this mechanistic understanding was that CO2 electrolysis could take amines and produce amides. Furthermore we repeated some of the experiments and could reproduce their results. Amines is a very broad class of chemicals, and the thought is that we can find an amine that can interact with the ethenone to form a high value product. Thus the goal of this direction is to both understand how the amide is formed and to produce a proudct of value.